frequently asked questions

WHAT IS ELECTRONIC FUEL INJECTION?

DO I NEED IDLE AIR CONTROL (IAC)?

You probably want one to help with cold starts, idling and smooth response from idle. All Borla V8 systems come with IAC for these reasons. The IAC consists of a stepper motor that can control the amount of air entering the intake manifold under direction of the ECU. There is also a small air filter on the inlet to remove particles from the air. For some engines the IAC motor and filter are mounted directly on the manifold. For other manifolds, space constraints may have the IAC as a separate assembly (remote IAC) that can be located elsewhere in the engine bay and connected to the manifold by a vacuum hose.

WHERE SHOULD I MOUNT THE INTAKE AIR TEMPERATURE SENSOR?

The ECU system needs to know the temperature of the air in the vicinity of the intake. The air temperature sensor need not be within inches though. As long as it is not close to any heat generating parts, it can be hidden near the wiring harness or even zip-tied directly to the harness.

IS MY EFI SYSTEM COMPATIBLE WITH E85 FUEL?

Yes, the components in the Borla fuel delivery system, including injectors, are suitable for use with E85.

WHAT ARE THE BRASS NUTS THAT CAME WITH MY V8 SYSTEM?

If your throttles mount to the manifold with studs, these self locking cad plated steel nuts are provided for use when finalizing installation. The systems are shipped installed with plain zinc plated nuts for temporary use in case the throttles need to be disassembled from the manifold.

WHAT CARBURETORS WILL BORLA THROTTLE BODIES REPLACE?

The DCO and DCOE Series Webers, the PHH Series Mikunis, the ADDHE Series Solex, the SK Racing sidedraft, the IDA (2 and 3 bbl) IDF and DCNF Series Webers, and DRLA Dellortos.

WHY DON'T BORLA INDUCTION THROTTLE BODIES HAVE VENTURIS LIKE CARBURETORS?

Carburetors rely on the pressure differential created by a venturi to draw fuel from the float bowl via the various jets and circuits. By their very nature these components cause a restriction to air flow, and contribute to pumping losses. The inevitable disadvantage of this system is that, while a venturi of a certain size may be necessary to provide low speed driveability it then acts as a restriction at high RPM. Because the fuel in an EFI system is injected under high pressure there is no need for any venturi. That is the reason throttle bodies flow so much more air than a carburetor of the same size and the reason that EFI systems can use larger throttles than the equivalent carburetors.

WHAT DO I NEED TO REPLACE CARBURETORS WITH AN EFI SYSTEM?

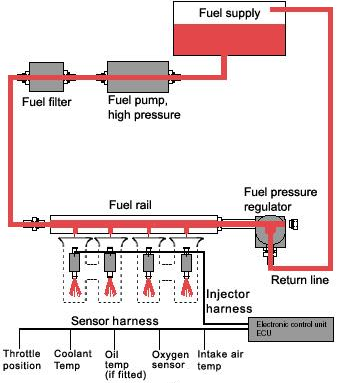

You will need a suitable manifold, throttle bodies to suit your application, a fuel rail kit, a high pressure fuel pump, a fuel filter and a fuel pressure regulator, appropriately sized injectors, a return line to the fuel tank or fuel cell, sensors (throttle position, MAP and air temperature) and an ECU kit.

WHAT IS A TYPICAL FUEL INJECTION SYSTEM LAYOUT?

This is a typical 4-cylinder installation where we assume that two of our DCOE throttles have been installed on a suitable manifold and the injectors are mounted in the throttle bodies.

Notes:

(a) Except when mounted in the fuel tank, fuel pumps should always be mounted below the level of the fuel.

(b) Calculate the fuel flow requirements of the engine, by estimating BHP and BSFC (brake specific fuel consumption, usually shown in pounds of fuel consumed, per horsepower/ per hour). This will provide a guide as to how much fuel pump capacity you will need.

(c) Fuel pressure regulators should always be installed downstream of the injectors.